Emerging Patterns in Commercial Central Heating Boiler Modern Technology for 2024

As you think about the landscape of commercial central heating boiler innovation in 2024, you'll locate on your own at the cusp of a transformative era. The sector is going through a substantial shift towards power performance, sustainability, and smart automation. With innovative functions such as intelligent warm recovery systems, IoT combination, and eco-friendly remedies acquiring importance, the inquiry arises: Just how will these advancements reshape the means business structures operate and eat energy? The solution depends on the nuanced interaction in between technology and effectiveness, setting the phase for an engaging development in the field.

Trick Takeaways

- Integration of IoT for real-time surveillance and control.

- Focus on environment-friendly and lasting services like renewable resource.

- Execute predictive maintenance approaches for effectiveness.

- Boost functional efficiency with clever automation systems.

- Utilize modular and scalable layouts for flexibility.

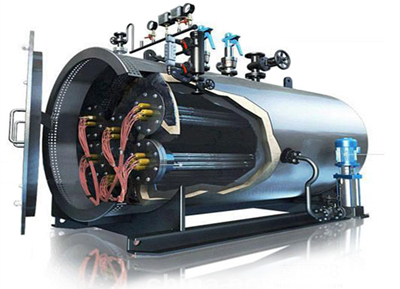

Improved Power Efficiency Features

Improve the energy efficiency of industrial central heating boilers in 2024 by integrating sophisticated modern technology and ingenious layout features. Energy-saving controls play an essential duty in achieving peak performance levels. By incorporating these controls, you can control the boiler's performance based upon real-time energy demands, reducing waste and improving general effectiveness.

Effectiveness optimization is an additional essential aspect to ponder. Executing functions such as smart warmth recuperation systems and advanced combustion systems can greatly boost the central heating boiler's performance. These advancements aid make the most of power use while lessening warmth loss, eventually resulting in set you back financial savings and environmental benefits.

Including advanced innovation and sophisticated design features into commercial central heating boilers is essential for remaining ahead in the sector. By concentrating on energy-saving controls and efficiency optimization, you can make certain that your boilers operate at peak efficiency while reducing power consumption. Accepting these advancements will not just profit your business but also add to a more sustainable future.

Assimilation of IoT Modern Technology

To optimize the efficiency of commercial boilers in 2024, consider incorporating IoT innovation for enhanced surveillance and control abilities. By integrating IoT combination, you can attain real-time surveillance of your boiler systems, permitting you to promptly deal with any kind of issues that may arise. This real-time monitoring not just enhances the performance of your procedures however likewise assists in recognizing potential problems before they rise, thus decreasing downtime and maintenance costs.

However, it's essential to address protection concerns when applying IoT modern technology. As you link your boiler systems to the web for surveillance and control, making certain robust cybersecurity measures is critical to secure against prospective cyber hazards.

Additionally, IoT assimilation surpasses monitoring; it also adds to power optimization. By examining data gathered through IoT sensing units, you can recognize patterns and trends in your boiler's efficiency, allowing you to make informed choices on optimizing energy use and taking full advantage of performance. Welcoming IoT technology in your industrial boiler systems can result in improved performance, improved security, and cost savings over time.

Surge of Environment-friendly and Lasting Solutions

The commercial central heating boiler sector is observing a substantial shift in the direction of the adoption of environment-friendly and sustainable services in 2024. Green building practices and lasting energy sources are coming to be significantly common as businesses aim to lower their ecological effect and operating expense. Business are currently more inclined to invest in boilers that line up with environment-friendly requirements, such as those that make use of renewable energy resources like solar energy or biomass.

Green structure methods are being integrated right into boiler modern technology to boost energy effectiveness and minimize carbon footprints. Producers are developing boilers with enhanced insulation, power management systems, and progressed combustion technologies to guarantee peak performance while reducing discharges. Furthermore, making use of sustainable energy sources such as geothermal or hydrogen is getting grip in the commercial boiler market.

Advances in Remote Keeping Track Of Capabilities

Among the developing landscape of commercial boiler technology, remote monitoring capabilities are undertaking considerable improvements. Real-time diagnostics and performance analytics play a crucial role in enhancing the efficiency and reliability of industrial boiler systems. By integrating advanced sensors and keeping track of devices, you can currently remotely track the functional standing of boilers in real time. This enables immediate recognition of any type of possible concerns or abnormalities, making it possible for positive upkeep and decreasing downtime.

With real-time diagnostics, you gain valuable insights right into the efficiency of your boiler system, permitting you to deal with concerns promptly and optimize efficiency. Performance analytics even more boost this capability by offering in-depth data on power consumption, operational trends, and total system health. By leveraging these remote surveillance advancements, you can make informed choices to enhance the efficiency and long life of your commercial boiler system.

Purchasing remote tracking capacities not only simplifies maintenance procedures yet also adds to set you back savings and operational performance. Accept these improvements to remain ahead in the ever-evolving landscape of commercial central heating boiler innovation.

Execution of Smart Automation Solutions

As industrial boiler innovation remains to development, the assimilation of clever automation systems is reinventing functional efficiency and control. Smart automation systems make it possible for commercial central heating boilers to run more efficiently by maximizing efficiency based upon real-time data and demand. By making use of sensors and progressed formulas, these systems can adjust setups immediately to ensure the boiler runs at peak performance degrees, resulting in substantial power financial savings and minimized functional expenses.

With clever automation, business central heating boiler systems can proactively determine possible problems before they rise, enabling prompt maintenance and stopping pricey downtimes. eco-friendly boiler installations london to from another location keep track of and regulate boiler operations with these systems boosts total functional effectiveness, permitting seamless modifications and fixing without the demand for consistent physical visibility.

Incorporating clever automation systems not just streamlines central heating boiler procedures yet also contributes to a much more sustainable and environmentally friendly technique to power intake in business settings. By using the power of data and automation, services can attain improved efficiency, lower power expenses, and enhanced operational integrity.

Evolution of Modular and Scalable Designs

Embracing modular and scalable layouts in business central heating boiler modern technology boosts flexibility and performance, leading the way for customized solutions customized to certain operational demands. By including versatile arrangements, business central heating boilers can currently be quickly adjusted to satisfy varying demands, whether it be changes in home heating needs or fluctuations in energy resources. These modular designs provide organizations the opportunity to optimize their central heating boiler systems according to their particular needs, leading to improved efficiency and power efficiency.

The evolution in the direction of modular and scalable styles also brings benefits relating to upkeep and upgrades. Parts can be conveniently changed or expanded without significant disturbances to the existing system, enabling smooth modifications as needed. This versatility not only decreases downtime yet additionally enables services to adjust swiftly to technical innovations in the industry.

Focus on Predictive Upkeep Solutions

You should focus on applying positive upkeep techniques, utilizing remote monitoring abilities, and embracing data-driven upkeep approaches to enhance the efficiency and reliability of your business central heating boiler systems in 2024.

These solutions can assist you forecast and prevent potential issues prior to they rise, eventually decreasing downtime and costly repair services.

Positive Maintenance Techniques

Executing sophisticated anticipating maintenance options can reinvent exactly how industrial central heating boilers are kept and operated in 2024. By incorporating condition-based tracking and anticipating analytics, you can stay ahead of prospective concerns and prevent expensive downtime.

Below are 4 crucial approaches to maximize your positive upkeep method:

- Utilize Real-Time Data: Carry out sensors to constantly keep track of central heating boiler performance.

- Anticipating Maintenance Organizing: Use information analytics to forecast upkeep needs and schedule jobs effectively.

- Abnormality Detection: Use formulas to spot inconsistencies from normal operation and flag possible troubles early.

- Integration with CMMS: Link anticipating upkeep tools with Electronic Maintenance Management Equipment for streamlined process and information administration.

Remote Surveillance Abilities

Enhance your maintenance method with remote monitoring capabilities to proactively resolve possible issues in industrial boiler systems via predictive maintenance solutions. Real-time diagnostics and anticipating analytics allow you to monitor your central heating boiler's performance continually.

By implementing condition monitoring, you can discover anomalies at an early stage, avoiding expensive downtime. These remote surveillance abilities allow for efficiency optimization, guaranteeing your boiler runs efficiently.

Through predictive maintenance services, you can set up upkeep at convenient times based on real system needs as opposed to generic timetables. This approach makes the most of the life-span of your devices while minimizing unforeseen failures.

Accept the power of remote surveillance to remain ahead of central heating boiler problems and enhance system efficiency.

Data-Driven Maintenance Approaches

Using data-driven maintenance approaches, particularly concentrating on predictive upkeep services, is important for optimizing the performance and long life of commercial boiler systems. By utilizing anticipating analytics and sensing unit technology, you can proactively determine potential problems prior to they intensify, reducing downtime and costly repairs.

Below are four crucial advantages of carrying out anticipating upkeep solutions:

- Improved Performance: Anticipating analytics allows for the surveillance of boiler performance in real-time, making it possible for modifications to maximize efficiency.

- Price Cost savings: By detecting problems at an early stage, anticipating maintenance aids prevent major malfunctions, saving on repair work expenses.

- Improved Security: Sensor innovation supplies essential data on central heating boiler conditions, boosting operational security for workers.

- Prolonged Equipment Life Expectancy: Anticipating upkeep helps in expanding the life expectancy of commercial central heating boiler systems by dealing with problems without delay.

Fostering of Crossbreed Heating Solutions

What benefits do hybrid heating systems provide industrial facilities concerning effectiveness and cost financial savings?

Hybrid furnace supply affordable options and power financial savings by effortlessly incorporating different heating technologies for peak efficiency. By incorporating traditional central heating boilers with renewable resource resources like solar or geothermal systems, hybrid systems can greatly reduce energy usage and functional prices for commercial buildings. These systems are developed to immediately change between power sources based on variables such as outside temperature, power costs, and system efficiency, ensuring that the building maintains a comfy temperature while making the most of energy effectiveness.

The seamless combination of several home heating innovations permits hybrid systems to leverage the staminas of each system, offering an extra flexible and effective heating solution for business establishments. This flexibility not just enhances power cost savings yet likewise adds to a more lasting procedure, lowering the environmental impact of heater in the long run. Generally, the fostering of hybrid heater provides commercial establishments a critical technique to boosting efficiency and accomplishing expense savings in their home heating procedures.

Often Asked Concerns

Are There Any Type Of Government Rewards for Taking On These New Technologies?

Federal government rewards can supply economic benefits for adopting new modern technologies. By making the most of these programs, you can conserve cash while buying much more reliable tools.

It is essential to research what rewards are readily available in your location and just how they can assist offset the initial expenses of updating to newer central heating boiler innovation.

Be aggressive in seeking these chances to maximize your financial savings and add to a much more sustainable future.

How Do These Innovations Impact the Total Cost of Installment?

When it comes to improvements in business boiler innovation, the influence on the general price of setup is considerable.

These developments can lead to cost financial savings by simplifying the installation procedure and decreasing labor expenditures.

With improved performance and easier integration, the general cost of installation can be reduced, making it an extra eye-catching choice for companies aiming to update their boiler systems.

What Are the Possible Cybersecurity Threats Associated With Iot Combination?

When it comes to IoT integration, potential cybersecurity dangers are a major concern for organizations. Information violations and privacy concerns can emerge if sufficient protection actions aren't in place.

It's critical to remain alert and implement strong security methods to protect your system against cyber threats. Be aggressive in attending to these threats and collaborate with experts to shield your information and keep the integrity of your network.

Can These New Equipment Be Easily Retrofitted Into Existing Infrastructure?

When considering retrofitting brand-new systems right into existing facilities, you might encounter difficulties as a result of compatibility problems and integration concerns.

It's essential to examine the feasibility of including these innovations effortlessly. Retrofitting can be complex, needing extensive preparation and possibly modifications to assure every little thing jobs efficiently.

Be prepared to address any compatibility concerns and assimilation concerns to successfully carry out these new systems right into your existing infrastructure.

How Do Crossbreed Home Heating Equipment Compare in Regards To Efficiency and Performance?

When comparing hybrid heating systems for performance and efficiency, it's essential to consider their capability to stabilize power financial savings and ecological impact.

These systems make use of a mix of resources like conventional boilers and sustainable modern technology. By incorporating different heating methods, hybrid systems can maximize efficiency while decreasing total energy intake.

This not just leads to cost savings however also adds to a greener impact, making them an encouraging option for lasting home heating remedies.

Verdict

To summarize, as an industrial structure owner or driver, you need to remain in advance of the curve by embracing the arising patterns in business boiler modern technology for 2024.

By focusing on energy efficiency, IoT assimilation, sustainability, and smart automation, you can enhance performance, lower downtime, and minimize energy usage.

Remain notified, adjust to brand-new technologies, and purchase ingenious services to assure your industrial boiler system satisfies the progressing demands of the market.